Fully welded fixed ball valve is suitable for cutting or connecting the medium in the pipeline of petroleum, chemical industry, thermal power station and other working conditions Class 150 ~ 300Lb and operating temperature -29 ~ 200℃.Applicable medium: petroleum, purified natural gas, acid natural gas, gas, water and coal slurry, etc.Operating mode: worm gear drive, pneumatic, electric, gas - liquid linkage.

Design specification: API 6D, ASMEB 16.34

Pressure - temperature classes: ASME B16.34, API608

Structure length: ASME B16.10, GB12221

Butt welding form: ASME B16.25, ASME B31.4/31.8

Inspection and test: API 598, API 6D, GB13927

Fire resistance test: API 607, API 6FA

Valve no. : Q361F

Connection: welding, butt welding

Pressure grade: Class 150~300Lb,PN1.6/2.5MPa

Product specification: DN600~1200mm

Product material: WCB, A105 F11, making, F304, F316, CF8, CF8M, WCC or optional according to customer requirements

Applicable temperature: -29℃≤ T ≤200 ℃

Suitable medium: water, air, oil and other fluids that do not react with carbon steel

Driving mode: worm wheel type

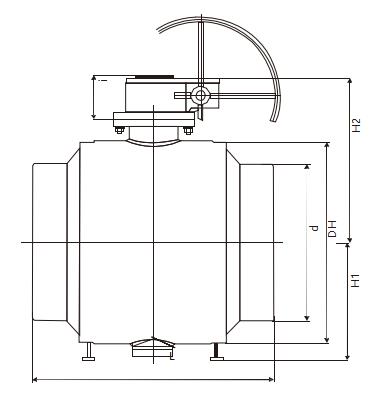

| DN(mm) | Nominal diameter | DH |

d A/B |

t | L | H1 | H2 | Weight(kg) |

|

600 |

600 |

1016 |

610/630 |

22 |

1143 |

650 |

860 |

2000 |

|

700 |

700 |

1130 |

7118720 |

24 |

1346 |

705 |

915 |

3100 |

|

800 |

800 |

1245 |

813/820 |

28 |

1524 |

770 |

1000 |

4700 |

|

900 |

900 |

1415 |

914/920 |

30 |

1727 |

855 |

1110 |

5700 |

|

1000 |

980 |

1555 |

1016/1020 |

32 |

1840 |

925 |

1180 |

6600 |

|

1100 |

1080 |

1700 |

1124 |

36 |

2100 |

995 |

1300 |

8100 |

|

1200 |

1166 |

1860 |

1219/1220 |

40 |

2100 |

1075 |

1430 |

11000 |